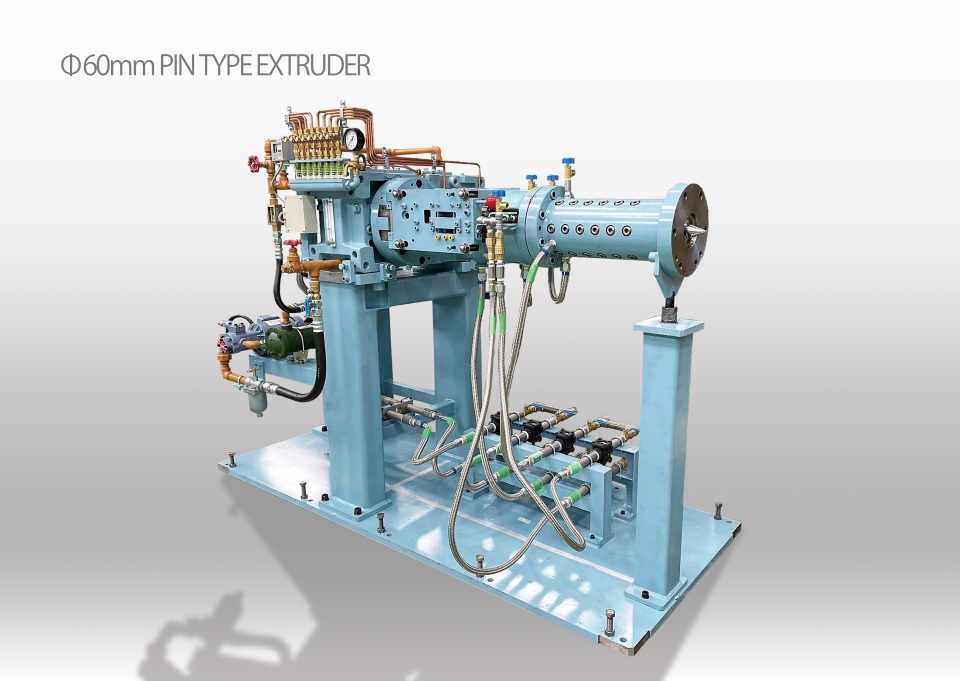

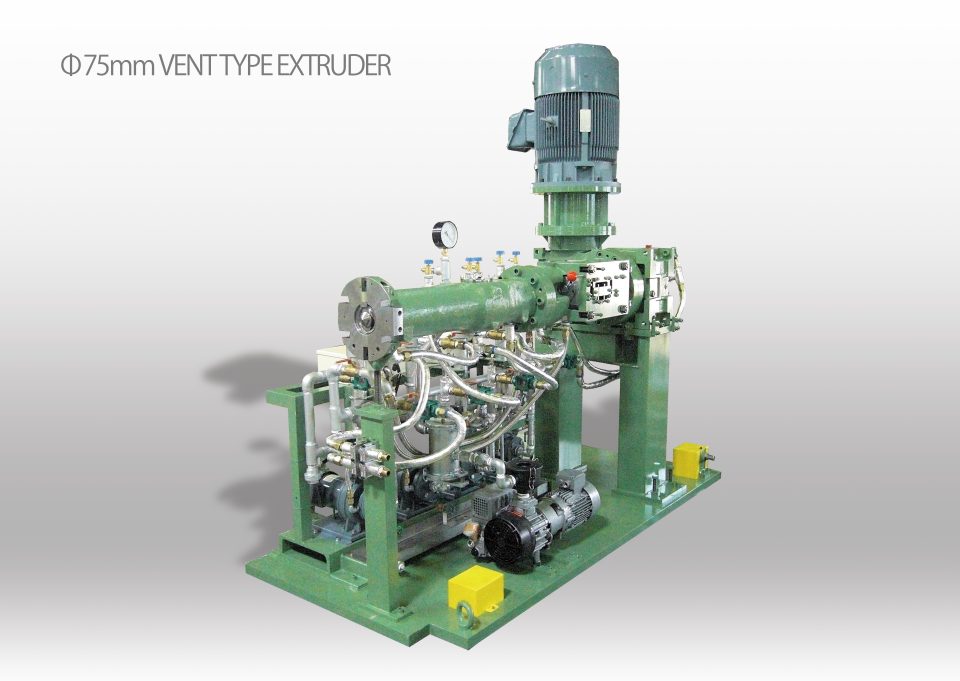

Variety of Our “Extruder” Peripheral Equipment

Overview

EXTRUDER EXCLUSIVE/PERIPHERAL EQUIPMENTS & DEVICES

Various equipments and devices relating the extrusion process, such as a Various Screws, Motorized Feed Roller, Gear Pumps etc. can be found here.

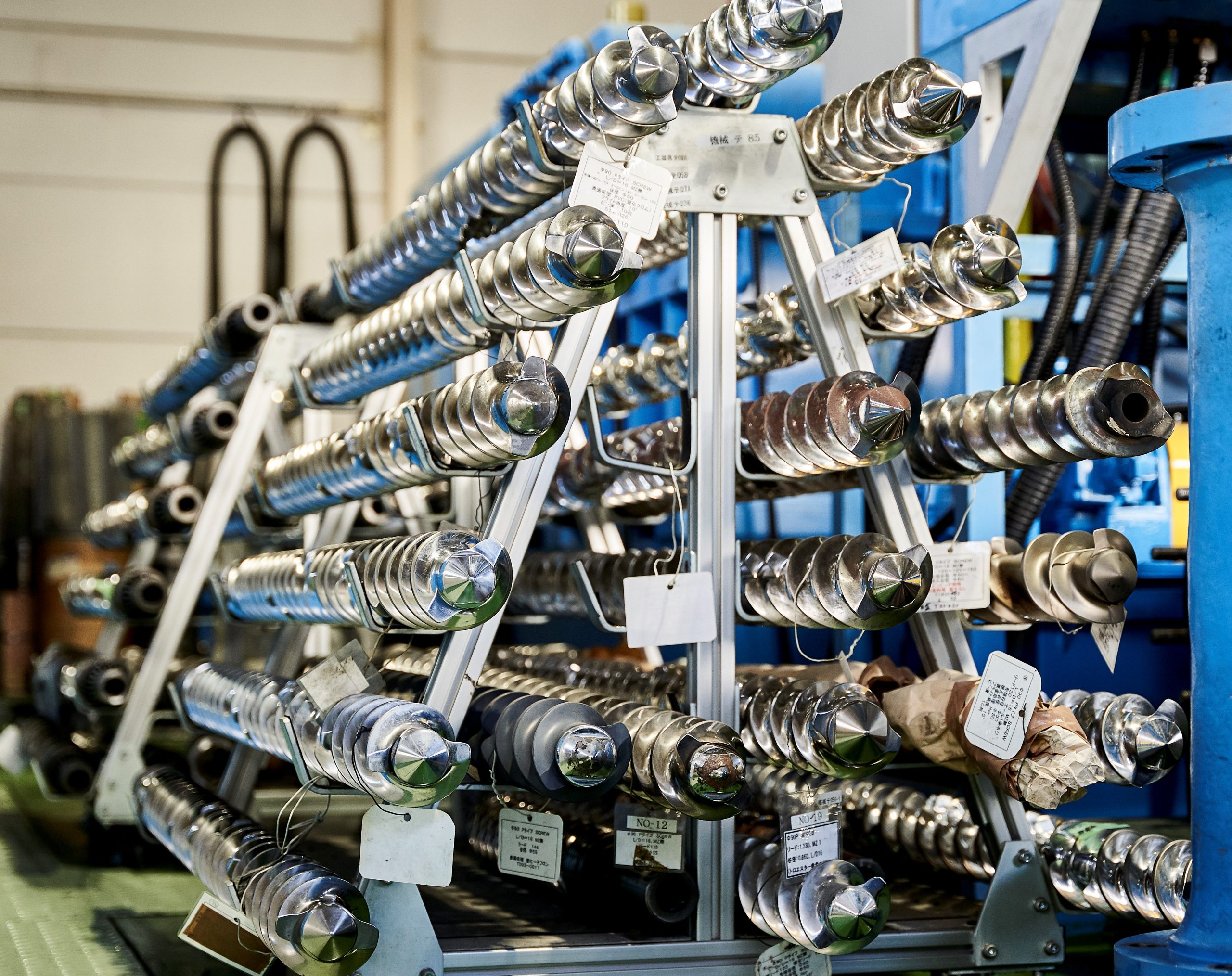

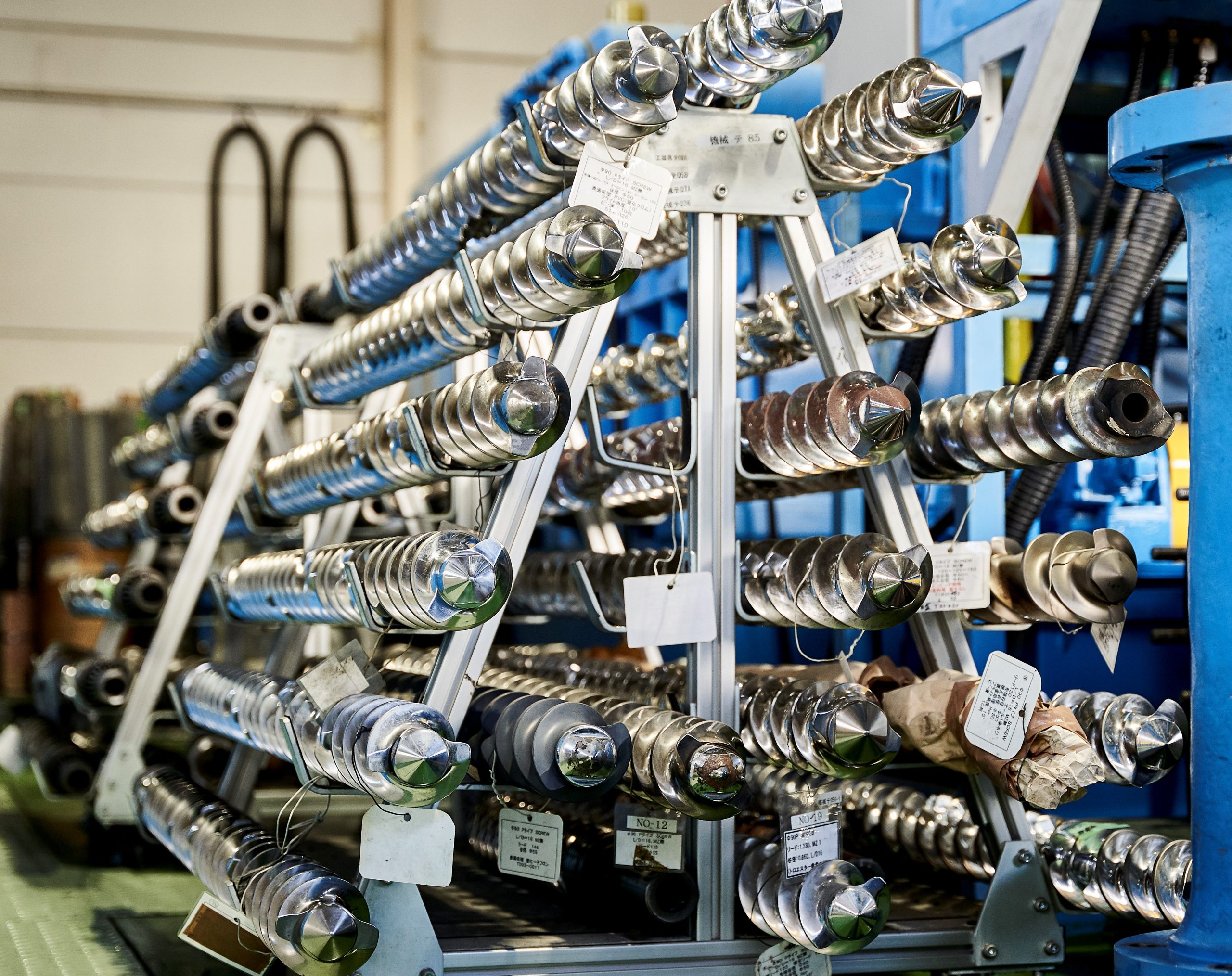

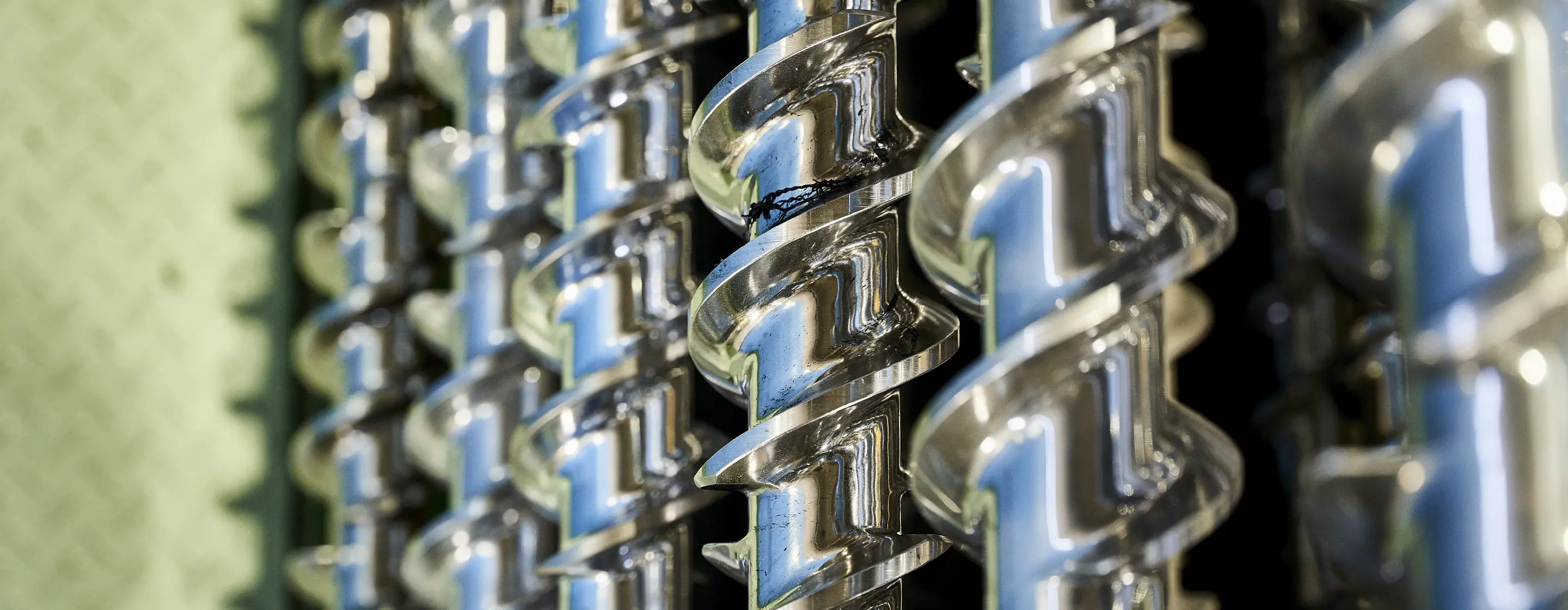

SCREWS

Customers can select a suitable screw to match their extrusion needs from an extremely wide variety of feed screw stocks. We accept an order for a custom-made screw in a special design.

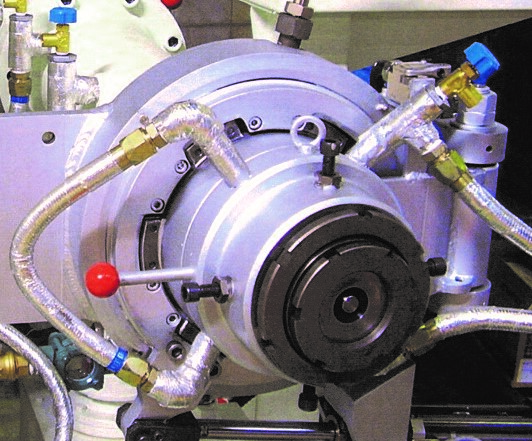

GEAR PUMPS

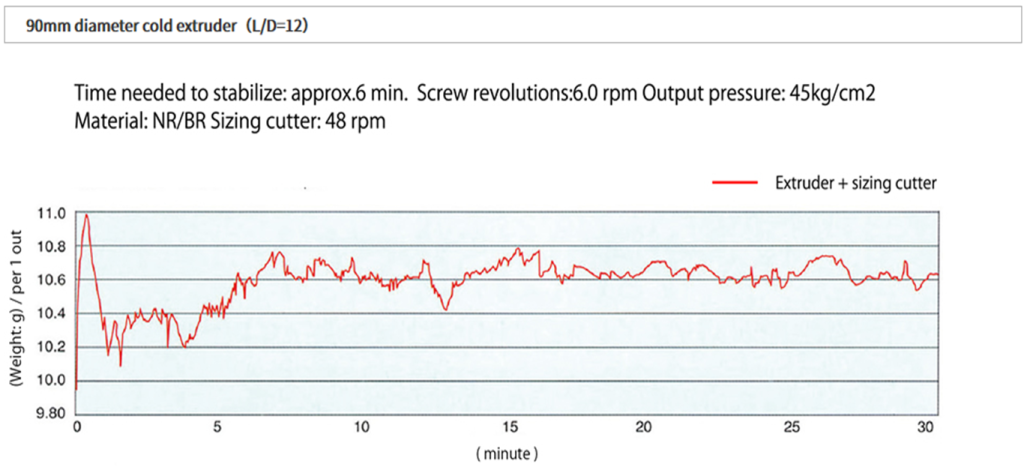

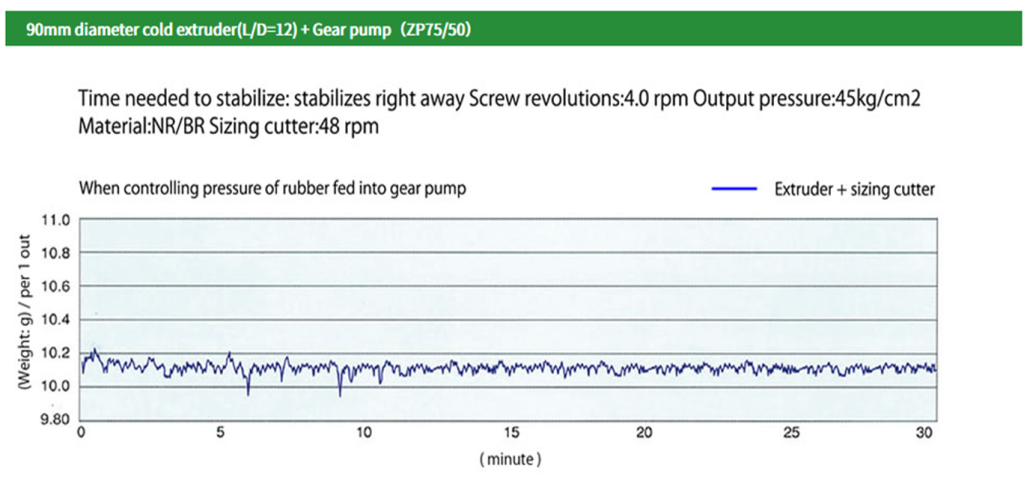

With a combination of extruder and gear pump, a variation can be reduced to 1% or less, while extrusion with a uniaxial extruder results in around 3%.

In combination with a cold, pin or vent type extruder, a gear pump can enhance the Nakata Extruders and allow them to work at the highest level of accuracy and quality.

Major Advantages : Gear Pump Combination Extrusion System

- Offers stable production extrusion regardless of changes in screw revolution.

- Offers speedy with the highest dimensional accuracy.

- Allows high die pressure.

- Avoids excessively high compound temperature.

- Increases output with high pressure.

- Avoids flooding on a vent type extruder.

- Is versatile and retrofittable to any extruder line.

- Minimizes rubber wastage. It offers an option to downsize the combination extruder.

MOTORIZED FEED ROLLER

A motorized feed roller is available for a customer who wants to change rotation speed ratio.

Variable Range

±30% against the standard rotation speed

Size Available (actual production result below, ask for the other sizes)

For φ60mm extruders – φ90mm extruders

Related products

-

The most suitable equipment to produce rubber prof……

-

The most suitable equipment to produce rubber prof……

-

The most suitable equipment to produce rubber prof……

-

EXTRUDER EXCLUSIVE/PERIPHERAL EQUIPMENTS & DEV……

-2-960x681.jpg)