DUPLEX EXTRUDERS

-2-scaled.jpg)

-2-scaled.jpg)

Overview

A tire consists mainly of components called tread and sidewall. In addition, each component consists of several rubber segments of different properties, so that the tire can demonstrate superior performances. In the older time, each rubber segment had been made individually. Then, a number of segments had been bound together to form one tire. A multiplex extruder eliminated such conventional processes. Today, several rubber segments can be all made in one component from the beginning, with excellent accuracy without trapped air in-between.

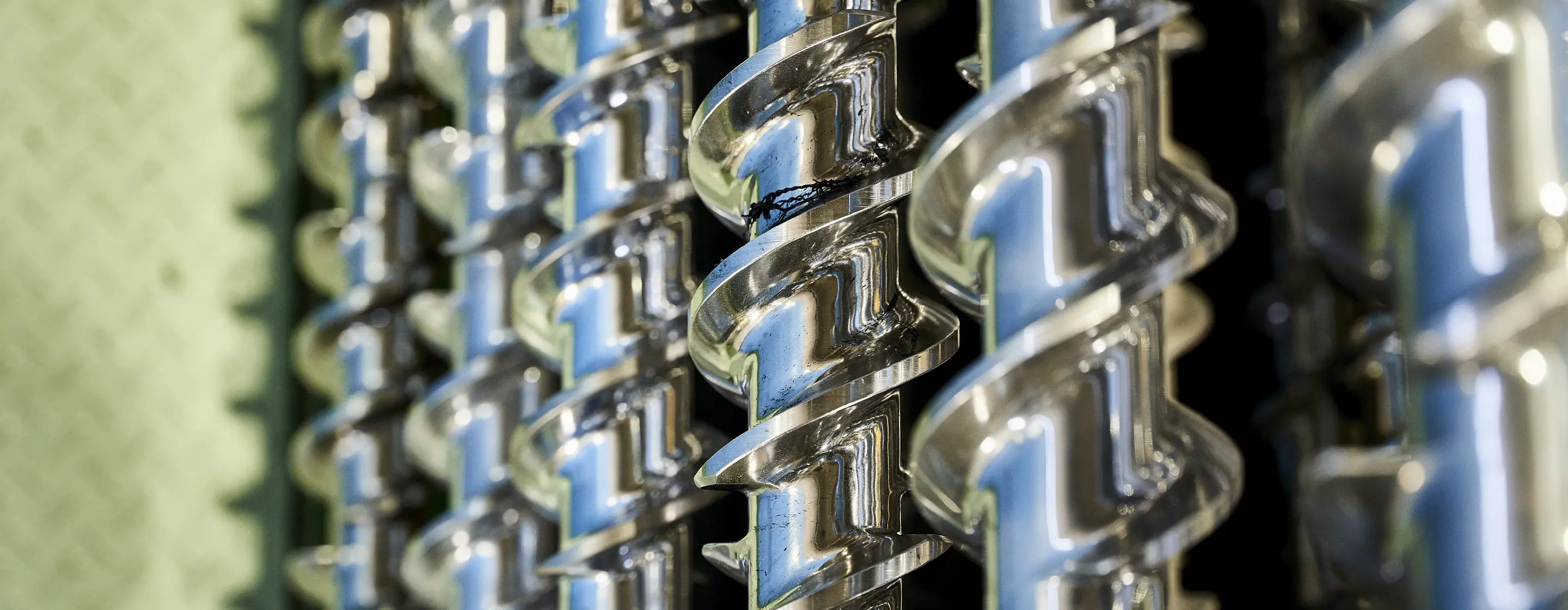

We, Nakata Engineering, provide the tire industry with both pick-a-back type and opposed type multiplex extruders. The former type has a head with 2 – 6 extruders vertically and radially stacked in line on its back. The latter one has a head with 2 – 4 extruders on its both sides. A Concentration of our latest technologies and long-term experiences makes us possible to develop the multiplex extruders and lead our industry.

DUPLEX EXTRUDERS

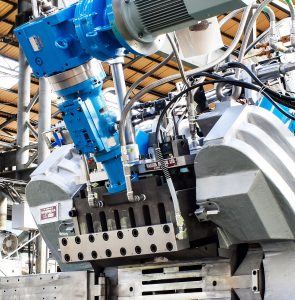

250Hx200P+45K chimney Duplex Extruder

Modification to Retrofit Chimney Extruder onto Existing Head

Nakata Engineering developed a technology to retrofit an extra-extruder for Chimney onto the existing head in a customer’s plant. We are pleased to comply flexibly with customer’s requirements and needs. Our unique preformer technology makes us possible to offer a service to mold the customer’s actual production profiles.

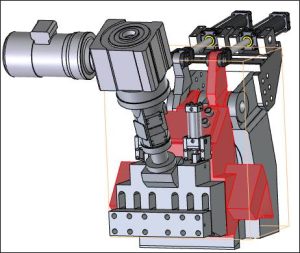

Wedge Penetration Chimney Technology Allows to Be Compact in Size

On the wedge penetration type, a Chimney compound is to be fed from the upper wedge and join together with a tread compound in the preformer. This mechanism allows us to design an extrusion head in compact size, compared to the stationary head penetration type. By changing merely the upper head and the wedge, your existing head can be modified into a Chimney applied extrusion system.

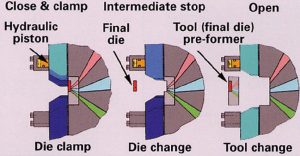

SHORT CHANGEOVER TIME

The Nakata extruder is designed so the final die change can be made in one minute. The upper tool clamping system can be stopped at a set intermediate position, enabling the final die to be changed with the pre-former still clamped, preventing rubber leakage between the head and the tool.

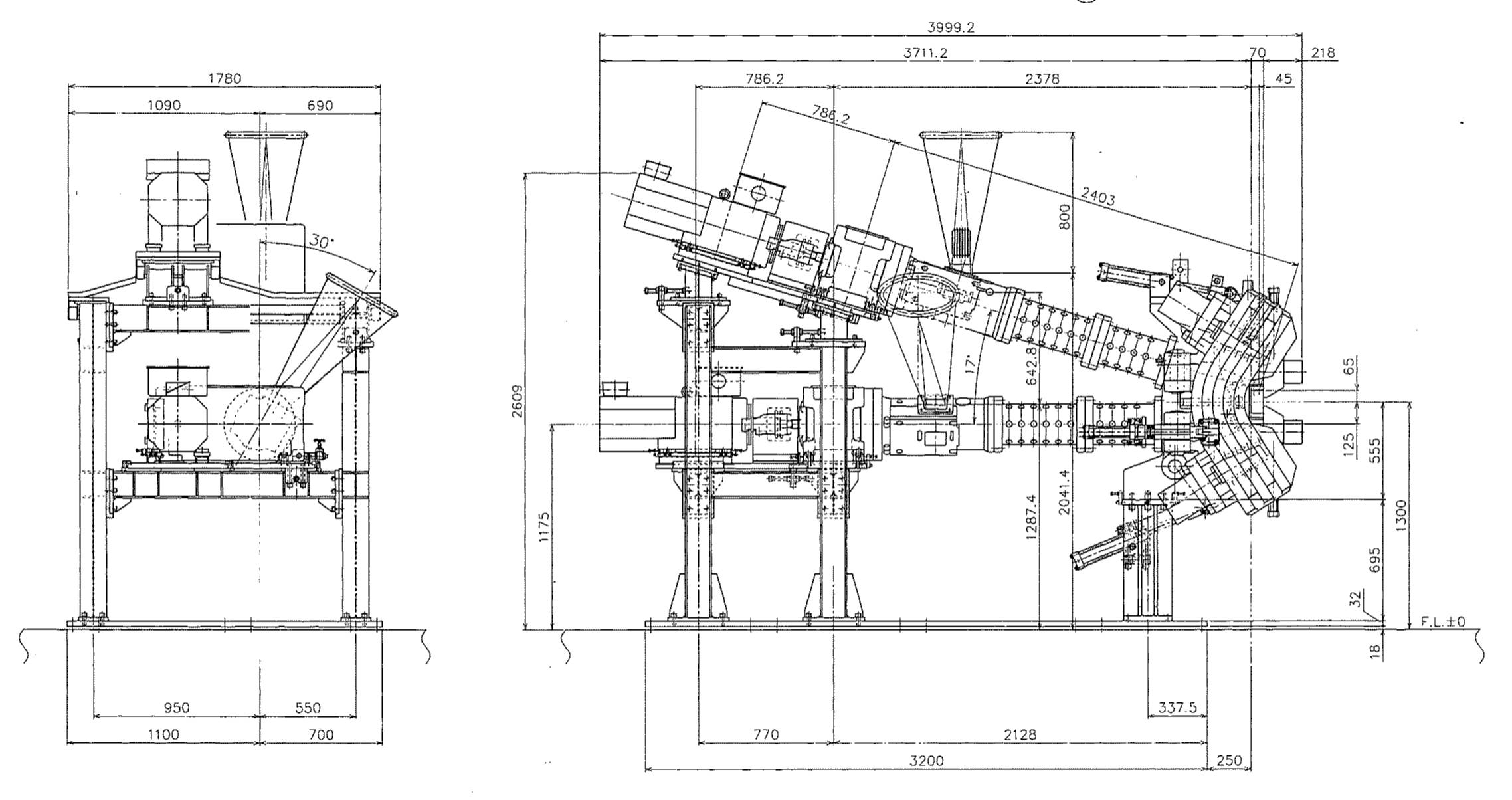

Specification

(Reference GA) (90Px90P)

Related products

-

The keystone equipment playing an extremely import……

-

The keystone equipment playing an extremely import……

-

The keystone equipment playing an extremely import……

-

The keystone equipment playing an extremely import……

-960x681.jpg)

-960x681.jpg)

-2-960x681.jpg)