ROLLER HEAD UNIT

Overview

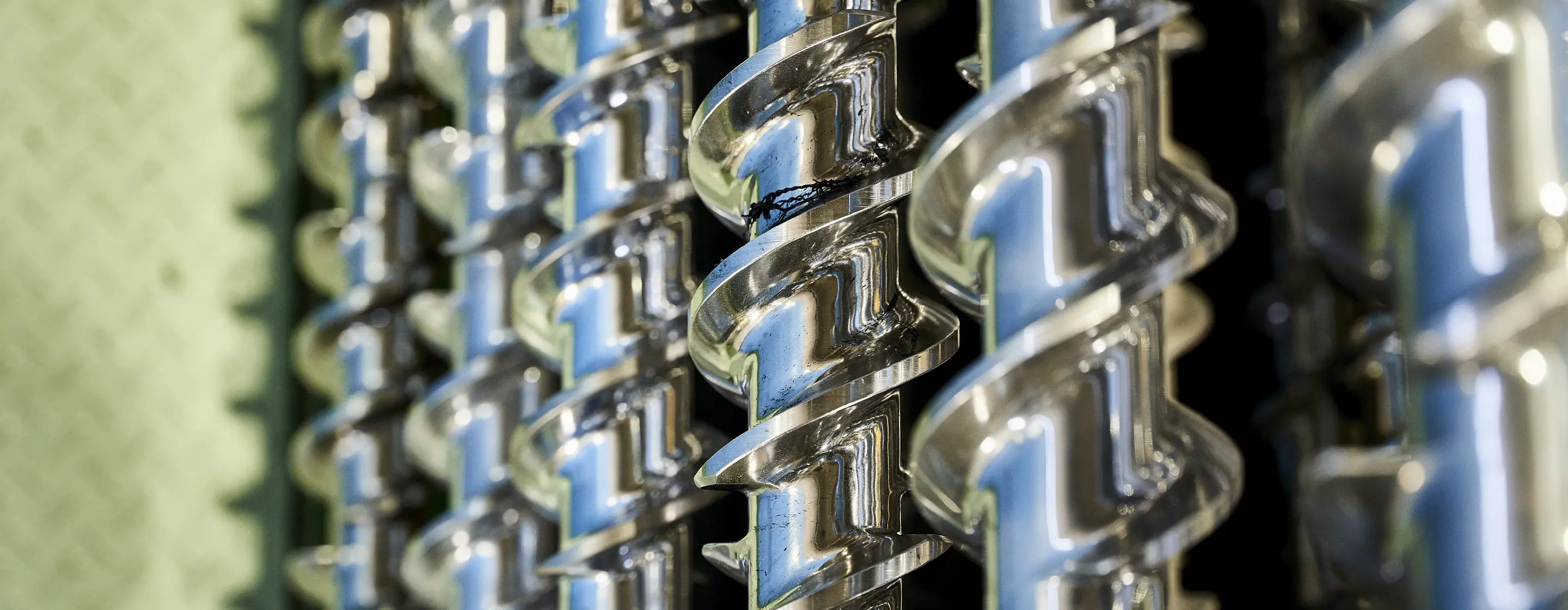

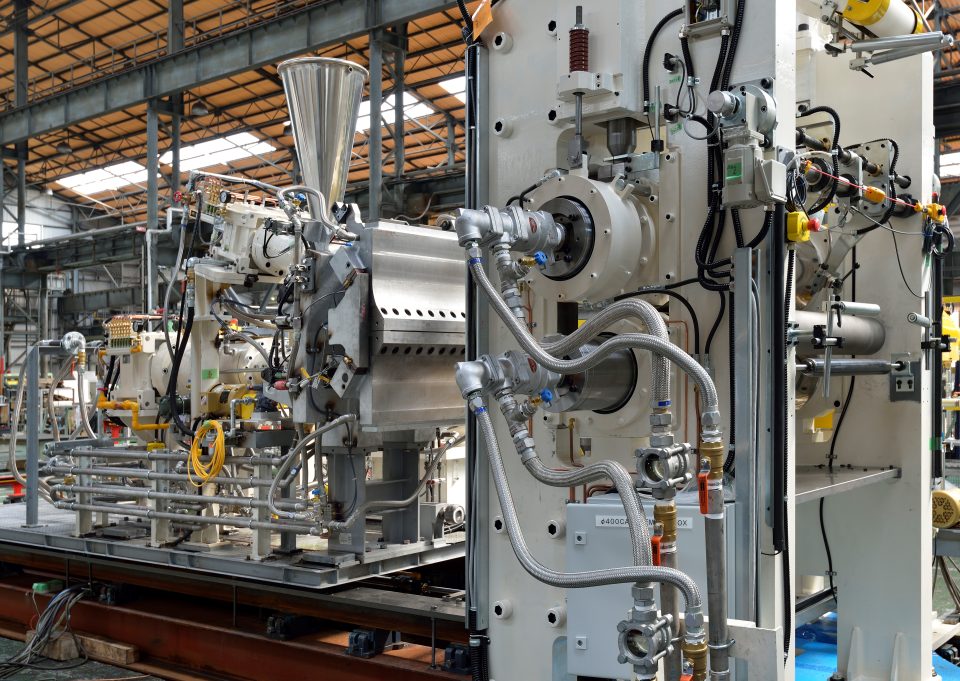

The roller head unit consists of a single or duplex extruder, a die head, and a vertical two-ball calender with head clamping devices. The broad width head and calender form the rubber compound into a sheet of uniform thickness, which can be varied from 0.5 mm -20 mm or greater in thickness. Nakata roller head units provide significant benefits over conventional calender systems in the production of inner liners, rubber sheets, V-belts, and elastic components.

Specification

Major Specifications of Extruder and Roller Head System

| Sheet head aperture | Calender roll | Product sheets | ||||

| Motor capacity kw | Width (mm) | Height (mm) | Roll diameter | Surface length | Width (mm) | Thickness (mm) |

| 200 | 1850 | 30 | <600> | <2000> | 1450 | 1.5〜9 |

| 450 | 2300 | 28 | 700 | 2500 | 2200 | 1〜15 |

| 300 | 1300 | 28 | 500 | 1500 | 1200 | 0.5〜4 |

| 200 | 1050 | 28 | 400 | 1300 | 270〜 | 0.5〜5 |

| 110 | 700 | 10 | 500 | 1500 | 1250 | 0.1〜1.0 |

| 45 | 600 | 22 | 310 | 900 | 500 | 1.5〜5 |

| 30 | 550 | 8 | 400 | 700 | 550 | 0.2〜2.0 |

| 18.5 | 185 | 5 | 200 | 250 | 100 | 0.5 |

| 7.5 | 95 | 3 | 120 | 150 | 100 | 0.3〜2 |

| 4.4 | 30 | 3 | 80 | 48 | 40 | 0.5 |

Related products

-

AUTOMATIC SLEEVE EXCHANGE ROLLER HEAD UNIT

Roller head unit that has advantageous characteris……

-

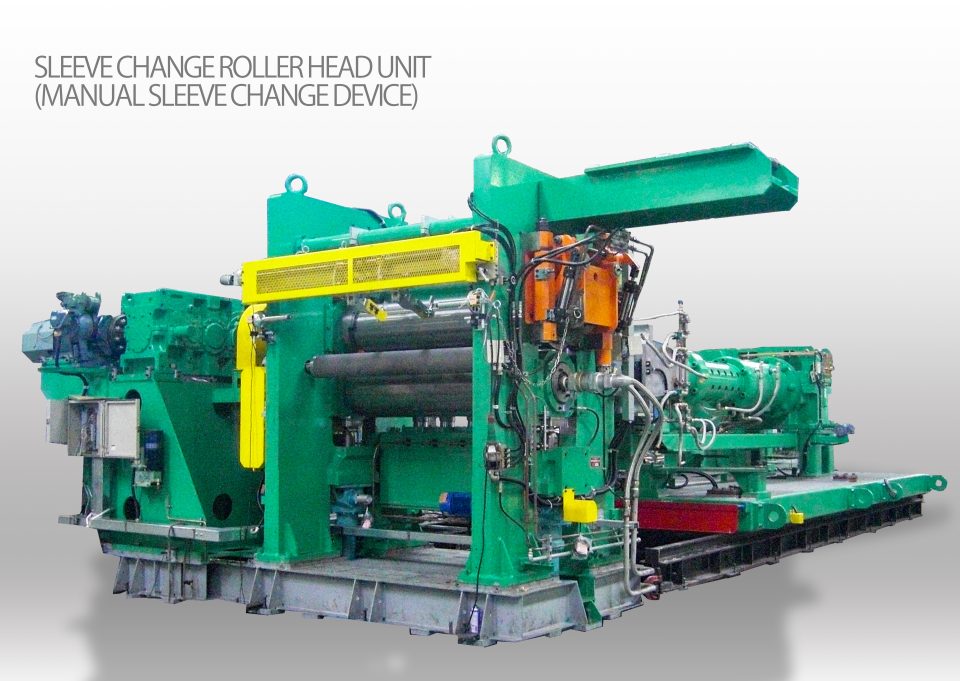

MANUAL SLEEVE EXCHANGE ROLLER HEAD UNIT

Roller head unit that has advantageous characteris……

-

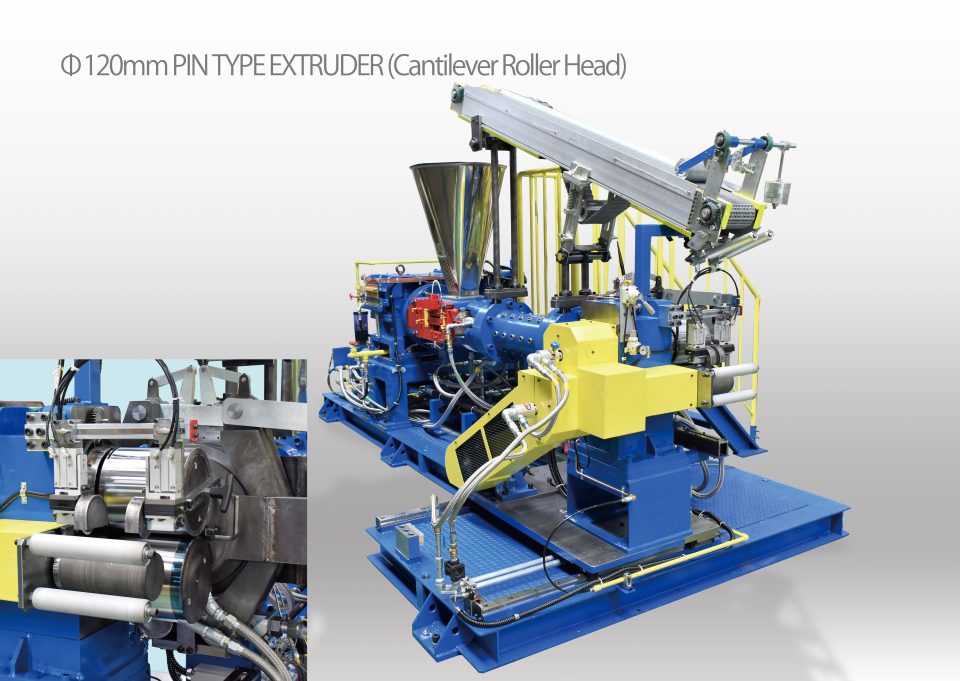

Roller head unit that has advantageous characteris……

-

Roller head unit that has advantageous characteris……