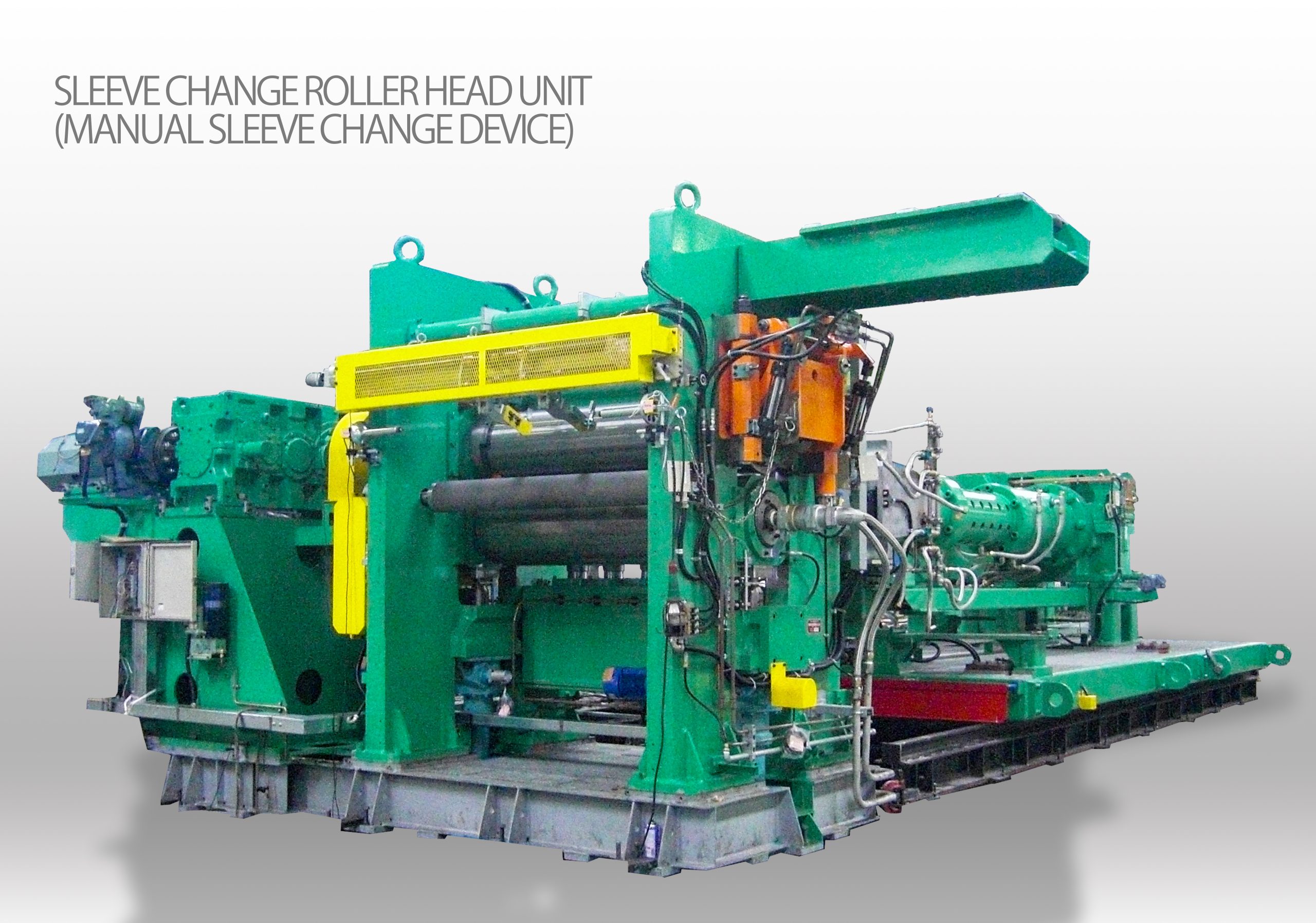

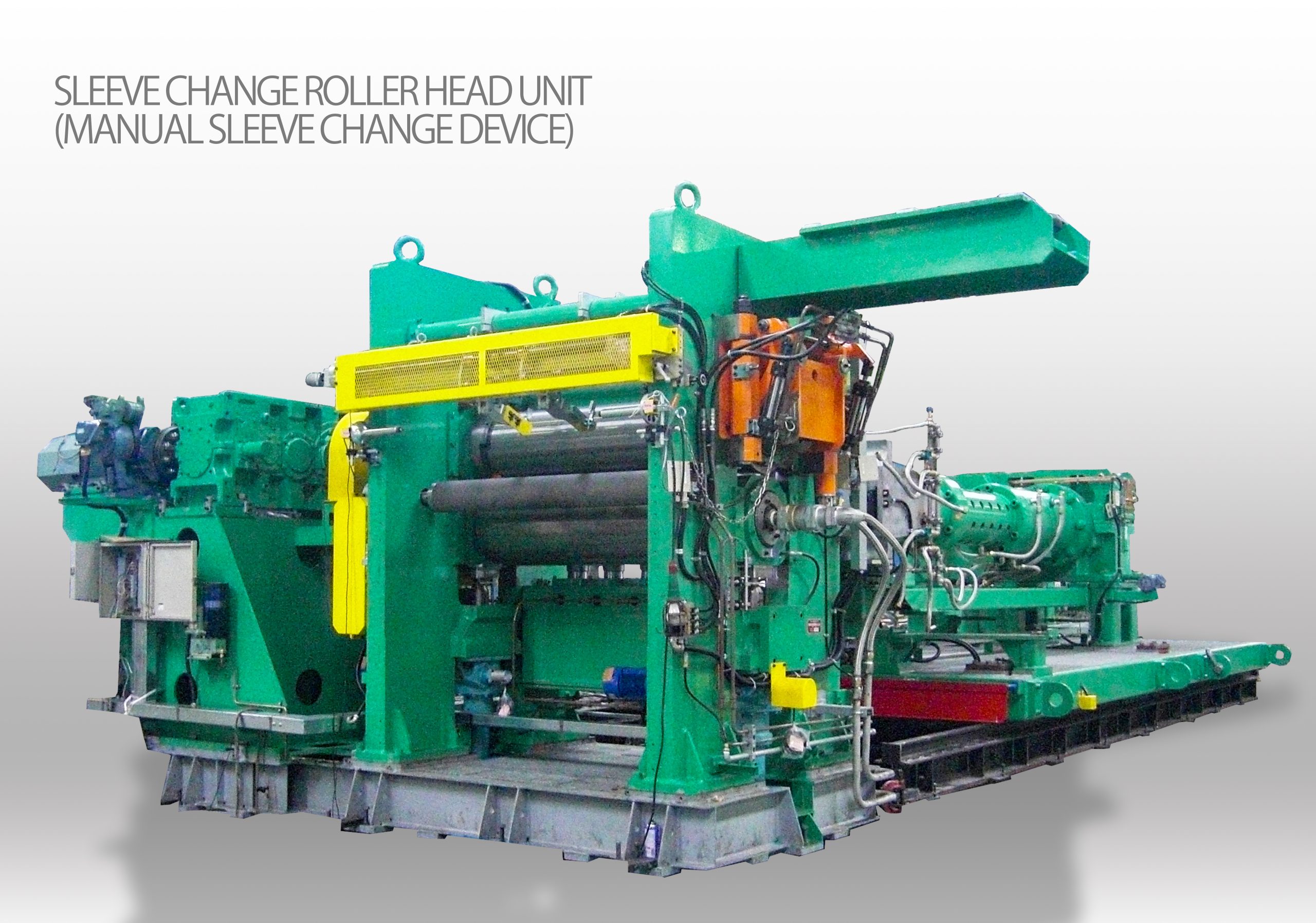

MANUAL SLEEVE EXCHANGE ROLLER HEAD UNIT

Overview

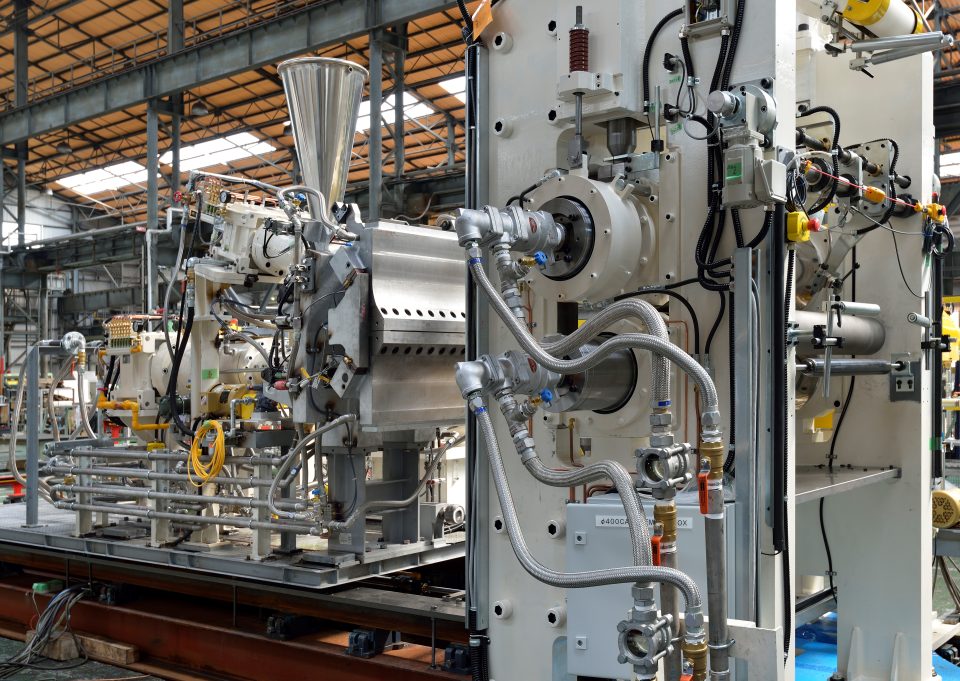

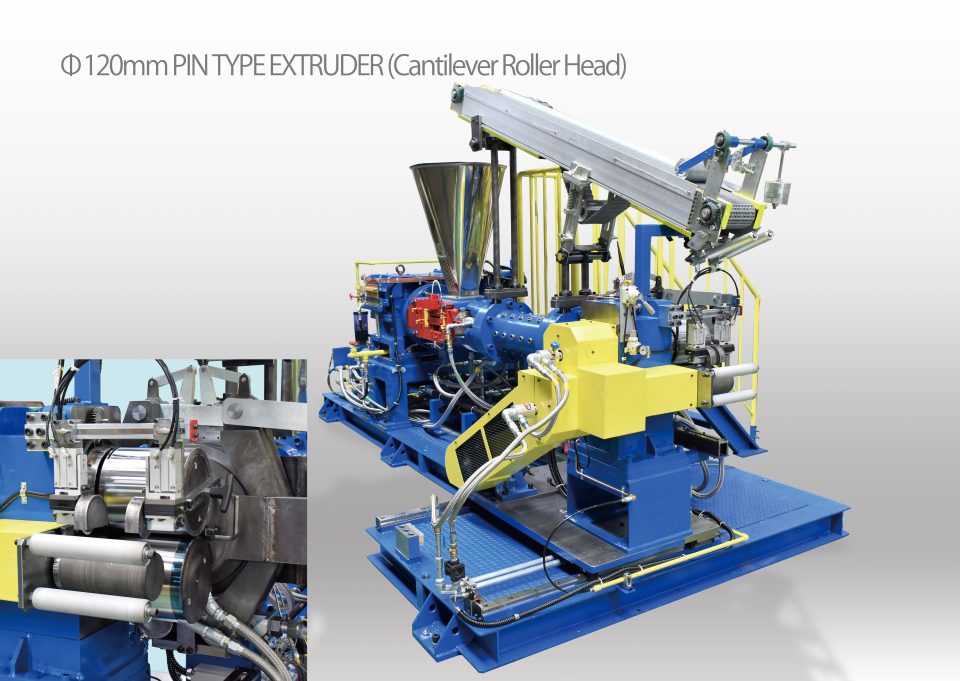

The roller head unit consists of a single or duplex extruder, a die head, and a vertical two-ball calender with head clamping devices. The broad width head and calender form the rubber compound into a sheet of uniform thickness, which can be varied from 0.5 mm -20 mm or greater in thickness. Nakata roller head units provide significant benefits over conventional calender systems in the production of inner liners, rubber sheets, V-belts, and elastic components.

MANUAL SLEEVE EXCHANGE ROLLER HEAD UNIT

The sleeve exchange roller head unit is used for profiled inner liner production for passenger, truck, and bus tires. The top roll of the calender incorporates a sleeve, which can carry a profile form. There is an automatic system for storing, preheating and changing the profiled sleeves within three minutes, resulting in high overall productivity and safety. With Manual (semi-auto) exchange system, it can be done within ten minutes. There is an automatic extrusion pressure control system to ensure the accurate thickness of profiled inner liners or profiled sheets in thickness from 0.5mm – 20mm. The unit is ideal for producing air bubble-free profiled inner liner for truck, bus and passenger car tires.

A wide variety of exchange mechanisms for different needs and applications

Nakata sleeve exchange roller head units are capable of offering both automatic and manual exchange depending on the customer’s operating environment. In the case of automatic exchange, all processes from insertion to and removal of the sleeve from the preheating furnace, to sleeve exchange, can be carried out automatically, resulting in an apparatus that excels in both productivity and safety. Manual exchange employs a specialized C-type hanger or Trolley, allowing easy attachment and removal of the sleeve.

Automatic sleeve exchange system

Manual sleeve exchange system (C-type hanger)

Manual sleeve exchange system (Trolley)

Pre-heating box

Pre-heating box, Sleeve stocker

Specification

Major Specifications of Extruder and Roller Head System

| Sheet head aperture | Calender roll | Product sheets | ||||

| Motor capacity kw | Width (mm) | Height (mm) | Roll diameter | Surface length | Width (mm) | Thickness (mm) |

| 200 | 1850 | 30 | <600> | <2000> | 1450 | 1.5〜9 |

| 450 | 2300 | 28 | 700 | 2500 | 2200 | 1〜15 |

| 300 | 1300 | 28 | 500 | 1500 | 1200 | 0.5〜4 |

| 200 | 1050 | 28 | 400 | 1300 | 270〜 | 0.5〜5 |

| 110 | 700 | 10 | 500 | 1500 | 1250 | 0.1〜1.0 |

| 45 | 600 | 22 | 310 | 900 | 500 | 1.5〜5 |

| 30 | 550 | 8 | 400 | 700 | 550 | 0.2〜2.0 |

| 18.5 | 185 | 5 | 200 | 250 | 100 | 0.5 |

| 7.5 | 95 | 3 | 120 | 150 | 100 | 0.3〜2 |

| 4.4 | 30 | 3 | 80 | 48 | 40 | 0.5 |

Related products

-

Roller head unit that has advantageous characteris……

-

AUTOMATIC SLEEVE EXCHANGE ROLLER HEAD UNIT

Roller head unit that has advantageous characteris……

-

Roller head unit that has advantageous characteris……

-

Roller head unit that has advantageous characteris……